Machine tools involve many moving parts to produce precision work. One of the most critical components of a machine tool is the spindle. Here at JTEKT, we are continually improving and expanding our inventory, skillset, and offerings to give our customers the best experience possible. Our new in-house machine component will allow us to test the quality of the rebuilt and refurbished spindles done here at our facility in the USA.

The timing is right for us to share some insights on high-frequency spindles and how ours stand out from our competition.

So, What is the High-Frequency Spindle?

Let’s begin with the basics by describing what a high-frequency spindle is. A fundamental component of machine tools is the spindle. A spindle is a rotating axis with a shaft at its center operating within a larger machine. Gearing drives most machine tool spindles.

There are a few different spindles that may be within one machine. Some of these spindles include the headstock and tailstock spindles. Some machines have up to 6 spindles known as multispindle machines. No matter the number of spindles, the driver will still be the main spindle.

The JTEKT High-Frequency Spindle Difference

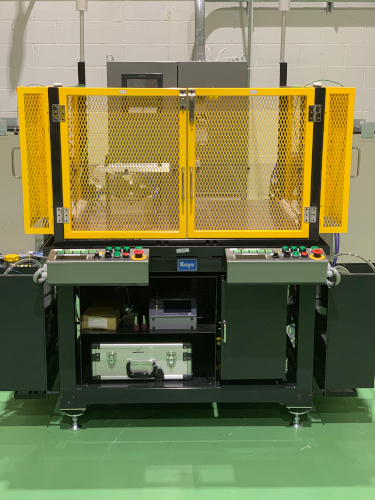

At JTEKT Machinery Americas Corporation, we are proud of our quality high-frequency spindles as a fundamental component of your test stand. Our high-frequency spindle test stands have a built-in motor that runs at a faster RPM than standard spindles while maintaining the high mechanical efficiency, low noise, and low vibration that your shop needs. We have chilled coolant and air mist systems keep the machine tool at a steady temperature despite demanding workload. The machines that can run the JTEKT high-frequency spindle include VG, SAM, MG, and KIH.

State-of-the-Art Machine Rebuild Center

Here at JTEKT, we build, service, and support all our products in our US-based location in Plymouth, MI. Being a full-service operation, we take pride in our top-quality products. We can offer you undiminished component quality by doing the work in-house, without involving any third-party companies. Our complete machine rebuild department offers options to dismantle and reconstruct your machine tools from the ground up.

JTEKT Machinery Americas Corporation offers high-quality engineering and grinding machines, components such as spindles, and consultations so you can get the best results from your machines. Give us a call today at (847) 253-0340 to speak with a precision grinding specialist.